MEERA CENTRUM

Workover Sequence Optimization

in the Middle East

Challenges

Solutions

OUTCOME

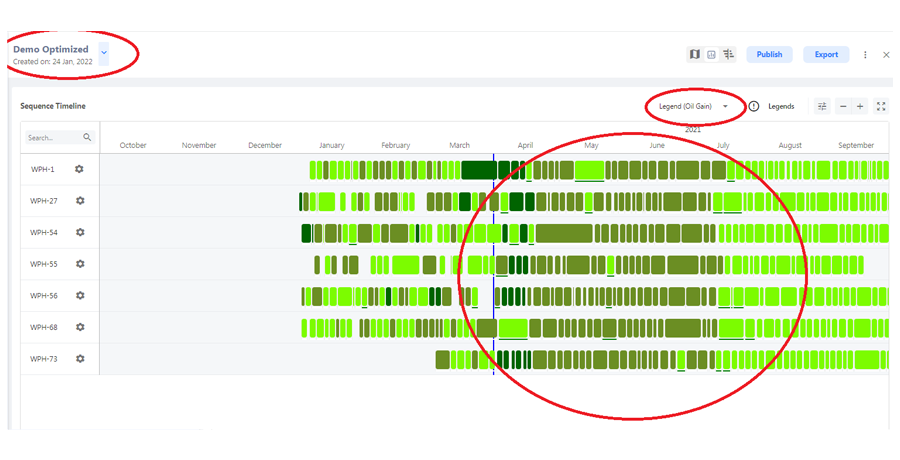

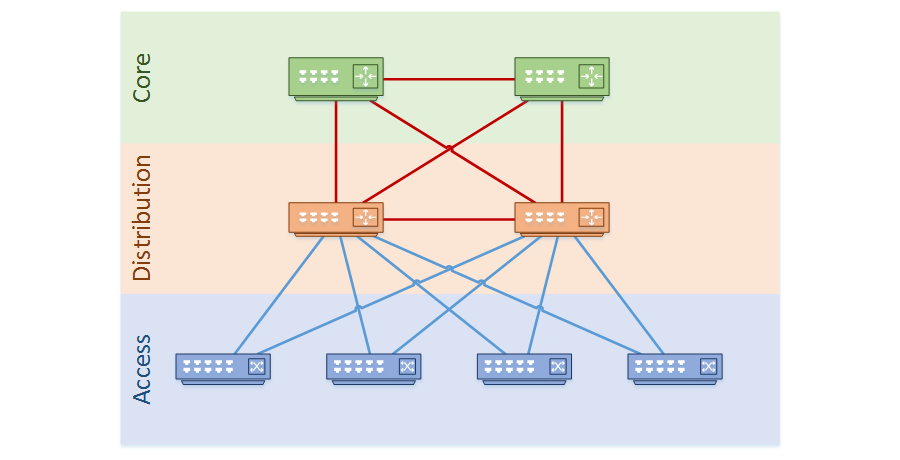

Optimized Multi-cluster Workover Sequence

A multi-cluster workover sequence model is constructed and connected to the client databases to fetch the updated information.

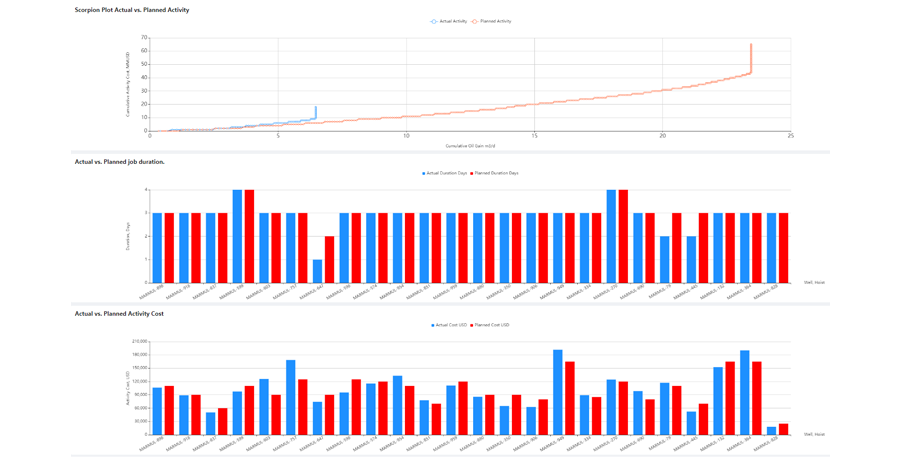

Optimized workover sequence generated which could be updated in minutes based on newly available data/constraint.

Hierarchical access granted to different users to import required data and observe/update the optimization parameters.

Using MEERA CENTRUM’s unique feature, the operator can estimate the expected profit from resolving each constraint and thus, can make informed decisions about extra investments such as increasing/decreasing the number of hoists.

Client Return on Investment:

Significant improvement in oil production acceleration and recovery

Significant Improvement

in Oil Production

Acceleration and Recovery

35.5%

28.3%

17.6%

additional production in the first 3 months

Reduction in operation completion time

Reduction in hoists movement