MEERA CENTRUM

Optimizing Water Flooding Plan in an Oilfield in the Middle East

Challenges

Solutions

OUTCOME

Optimized Field Plan and Confident Field Performance Prediction

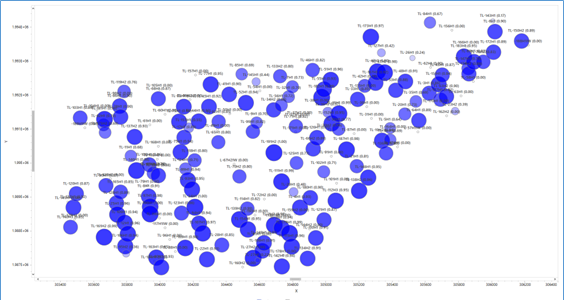

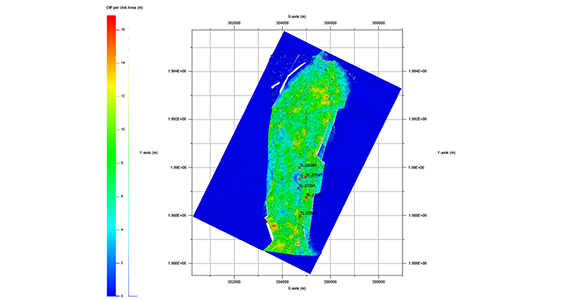

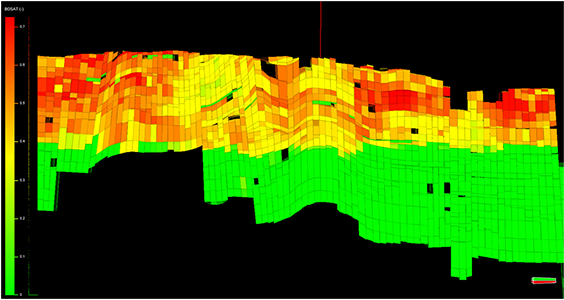

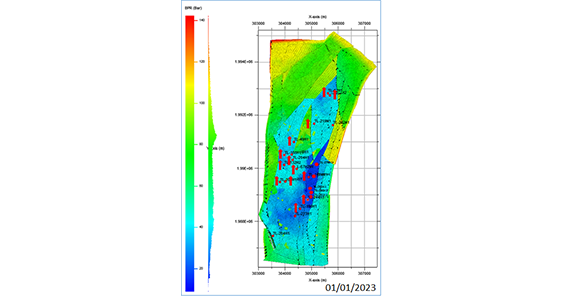

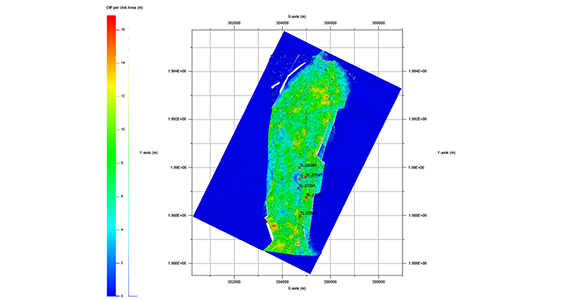

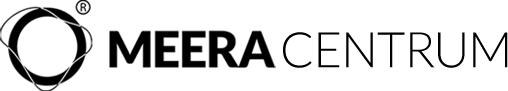

A full field Evergreen model is constructed and history trained in less than three weeks. The model shows excellent alignment with the observed data in the history and the blind test period which confirms the model’s predictability

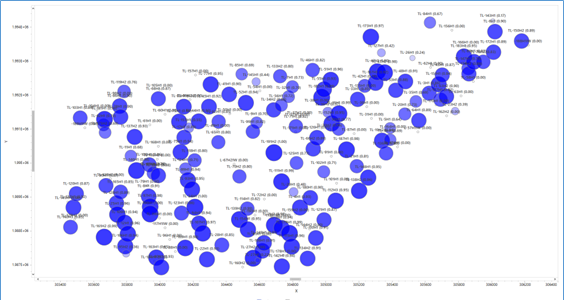

More than 100 development scenarios have been tried on MEERA CENTRUM super-fast model

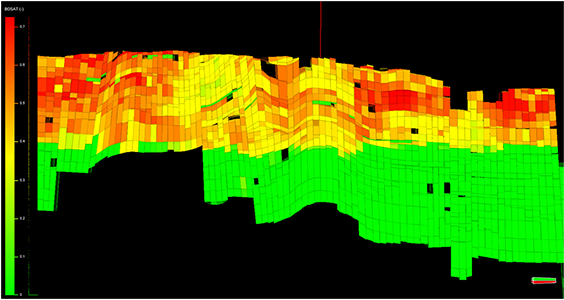

The location of 6 producers and 5 injectors has been optimized and proposed to the New Oil team

Perforation interval optimized in 5 existing producers and proposed to WRM team

The injection rate in 12 existing injectors has been optimized and proposed to the production team

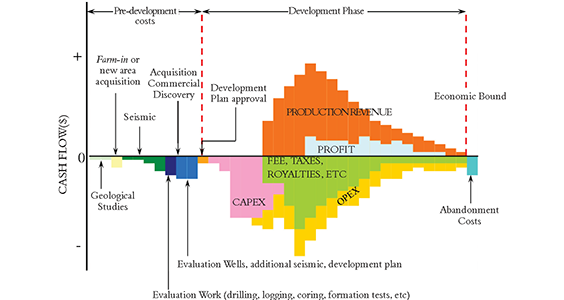

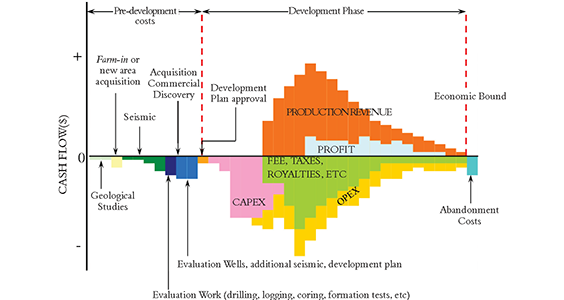

Economic Analysis was performed to evaluate the investment profitability

A full field evergreen model is constructed and history trained in less than three weeks. The model shows excellent alignment with the observed data in the history and the blind test period which confirms the model’s predictability

More than 100 development scenarios have been tried on MEERA CENTRUM super-fast model

The location of 6 producers and 5 injectors has been optimized and proposed to the New Oil team

Perforation interval optimized in 5 existing producers and proposed to WRM team

The injection rate in 12 existing injectors has been optimized and proposed to the production team

Economic Analysis was performed to evaluate the investment profitability

WHAT WE DELIVER

History training & forecasting time comparison

MEERA CENTRUM

CONVENTIONAL

0.9hours

5.7hours

MEERA Single run

CMG Single run

4-5runs

100-200runs

MEERA

History matching runs

Conventional

History matching runs

Client Return on Investment:

4.6% Improved Oil Production

4.6% Improved

Oil Production

2.9%

1.5%

0.2 %

Improved oil Production in 3 years, by relocating 8 production wells

Improved oil Production in 3 years, by relocating 5 injectors and adjusting injection rates for 12 existing wells

improved oil Production in 3 years, by optimizing the perforation interval in 5 wells

Estimated Cost Effectiveness

MEERA CENTRUM

CONVENTIONAL

IMPROVEMENT(%)

MEERA CENTRUM

CONVENTIONAL

IMPROVEMENT(%)

-

-

5.7%

MEERA | Total Expected Oil Production

Conventional | Total Expected Oil Production

Total Expected Oil Production

10man-months

15man-months

33%

MEERA | Normal FDP Study from Scratch

Conventional | Normal FDP Study from Scratch

Normal FDP Study from Scratch

Automatic

11man-months

100%

MEERA | Frequent Model Updates (every 2-5 years)

Conventional | Frequent Model Updates (every 2-5 years)

Frequent Model Updates (every 2-5 years)

7man-months

10man-months

30%

MEERA | Project Duration

Conventional | Project Duration

Project Duration

Young Engineers

Senior REs

70%

MEERA | Resources Requirements

Resources Requirements | Industry Estimated

Resources Requirements

Not Required

Required

30%

MEERA | Compositional model

Conventional | Compositional model

Compositional model

Normal System

Workstation or cluster

30%

MEERA | Hardware & Maintenance

Conventional | Hardware & Maintenance

Hardware & Maintenance